Tower Cold Chain Unveils an Industry-First Container Design

Tower Cold Chain, a leader in passive temperature-controlled containers, has unveiled the KTEvolution 12, setting a new standard in small parcel solutions for pharmaceutical products, thanks to its unique plate design.

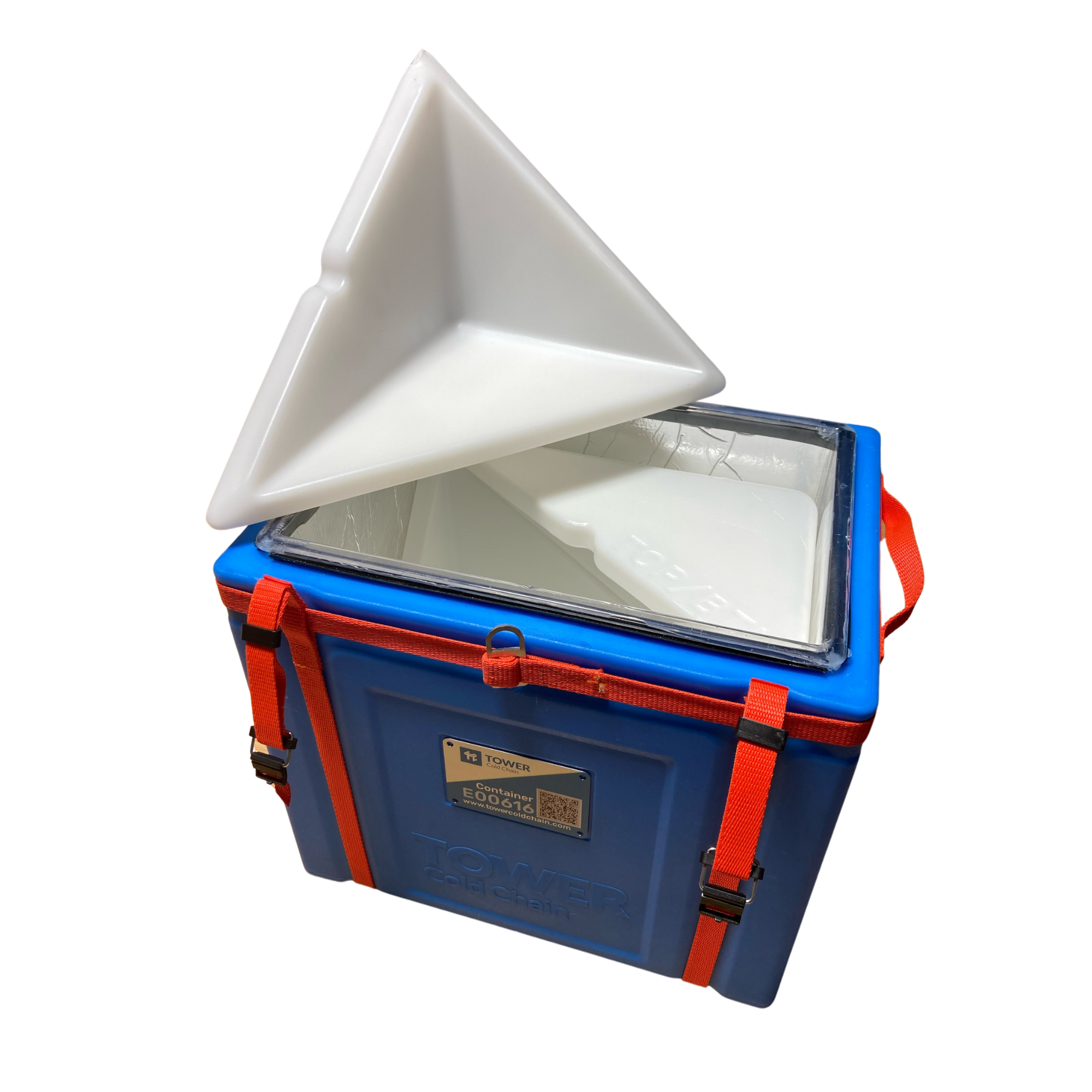

Unveiled at LogiPharma 2024, the KTEvolution 12 integrates Tower’s existing phase-change materials (PCM) or dry ice into a new pyramid-shaped configuration. This patent-pending plate system guarantees improved internal temperature consistency even when the container is placed on its side – a first in the cold chain sector.

Purpose-built for last-mile delivery, laboratory distribution, and clinical trials, The KTEvolution 12 provides the safe transport of thermally sensitive products requiring internal temperatures ranging from <-60°C to above +20°C with maximum product protection.

Tailored specifically for the transportation needs of life science products, including high-value commercial products, cell and gene therapies, as well as research and development shipments, the container provides optimal security throughout the pharmaceutical supply chain.

With an internal payload up to 12 litres, Tower’s latest product maintains thermal control for over 96 hours without the use of external power or human intervention during transit, meaning products can be reliably shipped both domestically and internationally in a parcel-sized box

“The KTEvolution 12’s innovative design not only ensures superior temperature consistency but also prioritises durability and sustainability,” said Martin Hawes, Global Head of Product Development at Tower Cold Chain. “With a 30% increase in thermal performance compared to semi-reusable solutions, our newest container exemplifies Tower’s commitment to pushing the boundaries of sustainable cold chain technology.”

Tested to ISTA7D summer and winter methodologies, the KTEvolution 12 emerges as the optimal solution for managing unexpected shipping disruptions effortlessly. Featuring a robust outer shell constructed from three layers, including lightweight vacuum insulated panels, the container ensures maximum longevity.

Strategically positioned recyclable polyethylene foam provides targeted protection against impact and shock during transit, rendering the KTEvolution 12 a fully sealed, hard-shelled unit. This design not only guarantees weatherproofing and washability but also minimises the risk of microbial and bacterial contamination of products, aligning with circular economy principles.

Designed for ease of handling and maintenance, the KTEvolution 12 can be equipped with IoT capabilities for real-time data logging and GPS live tracking, providing customers with full visibility and control over their shipments.

“The KTEvolution 12 not only delivers enhanced performance but also provides additional protection and efficiency. This advancement reinforces Tower’s commitment to delivering robust, reliable, and reusable cold chain logistics solutions on a global scale,” said Niall Balfour, Chief Executive Officer at Tower Cold Chain.

The KTEvolution 12 offers unparalleled customisation advantages, ensuring tailored solutions for customer’s specific needs. From personalised branding to compatibility with all temperature ranges and IoT integration, the KTEvolution 12 can be tailored to meet the unique requirements of shipments, providing maximum flexibility and efficiency for pharmaceutical manufacturers.

For more information on purchasing the KTEvolution 12, visit: www.towercoldchain.com/ktevolution-12