- Solution overview

- System Specifications

- Evaluation Criteria

- Documentation

Solution overview

Tower’s advanced insulated food boxes allow airlines and rail operators to transport hot or cold food without relying on dry ice or setting up dedicated supply chains at each location. This supports return catering, reduces food waste, and makes it possible to uplift catering from base for short-haul routes—while still meeting food safety requirements for up to 24 hours.

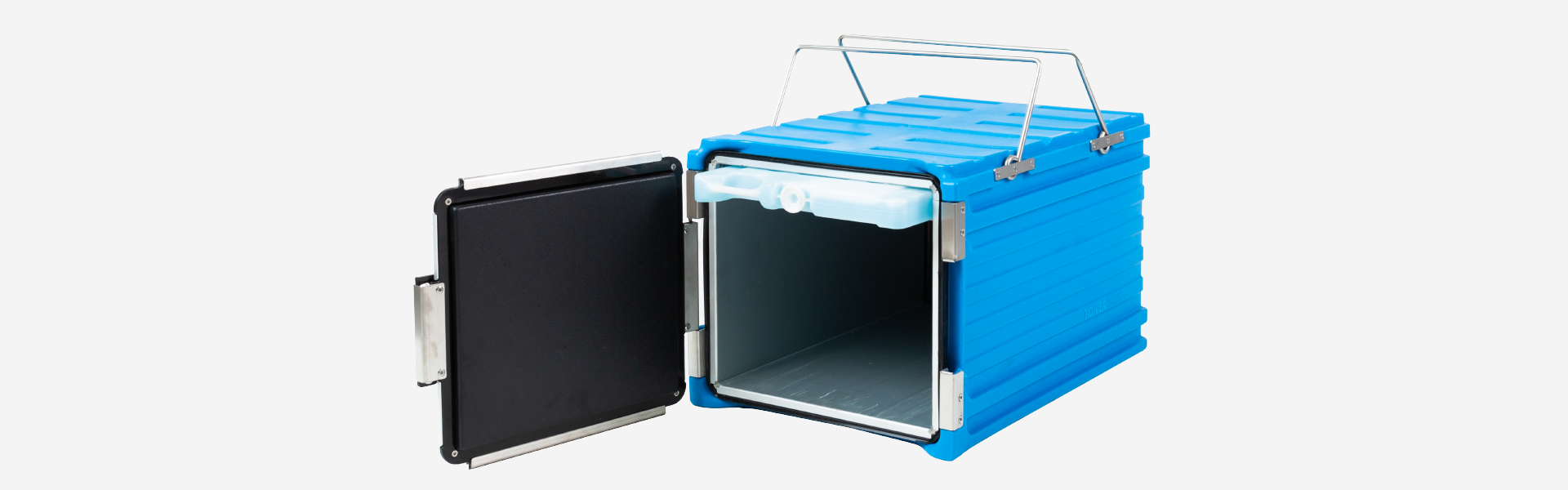

Each insulated food box is designed to fit seamlessly into standard ATLAS airline and rail carts, ensuring easy integration into existing galley space. Whether used for food delivery or food storage, the system keeps contents protected throughout transit.

Tower Cold Chain’s robust, reusable food carriers provide physical and temperature stability for onboard catering. Though not made of stainless steel, the durable construction and advanced vacuum insulation technology offer the reliability required to prevent spoilage and maintain a secure cold chain.

Trusted by more than 60 global airline, rail, and catering partners, Tower’s food boxes have been in continuous service since 2015, improving the onboard passenger experience and supporting safer, more efficient operations.

Available to lease or purchase, Tower’s Airline Insulated Boxes deliver a consistent, compliant, and cost-effective catering solution for operators worldwide.

System Specifications

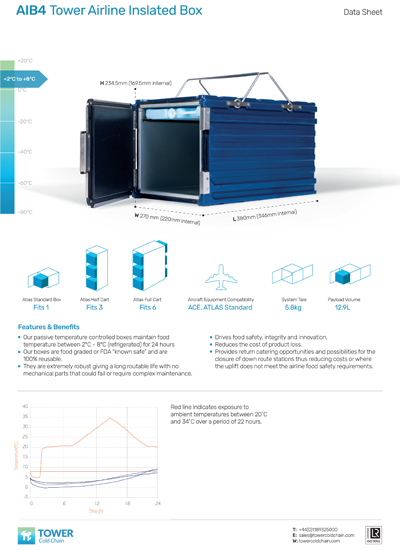

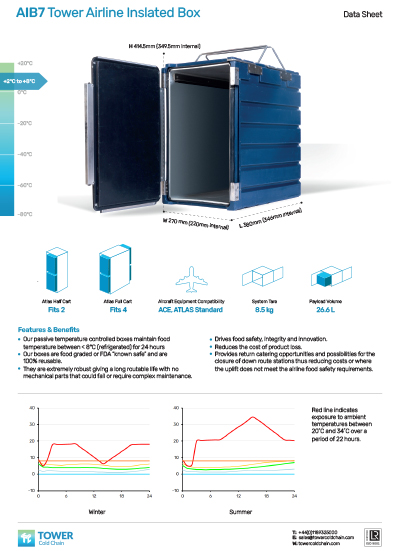

| AIB4 | AIB7 | Phase Change Plate | |

|---|---|---|---|

| Container | Airline Insulated Box (4 runner) | Airline Insulated Box (7 runner) | Fits AIB4 and AIB7 |

| Description | ACE, ATLAS Standard | ACE, ATLAS Standard | PCM Plate |

| Aircraft/Rail Equipment Compatibility | ACE, ATLAS Standard | ACE, ATLAS Standard | ACE, ATLAS Standard |

| Temperature Control | <+ 8 for 24 hours | <+ 8 for 24 hours | <+ 8 for 24 hours |

| External Dims (mm) | 380 x 270 x 234.5 | 380 x 270 x 414.5 | 207 x 23 x 337 |

| Payload Dims (mm) | 346 x 220 x 169.5 | 346 x 220 x 349.5 | N/A |

| Weight | 4.6kg | 6.8kg |

Evaluation Criteria

- The Tower boxes enable airlines and train operators to carry food without compromising safety standards or creating dedicated supply chain networks at each station.

- Provides return catering opportunities and possibilities for the closure of down route stations thus reducing costs.

- Allows catering to be uplifted from base for short-haul routes where the uplift does not meet the airline food safety requirements.

- Provides product consistency.

- Our technology enables food to be stored for up to 24 hours within legal safety temperature requirements.

- Our AIBs are made of a unique lightweight durable polymer material and are 100% reusable.

- Eliminates the need for dry ice

- Our AIBs fit into Atlas catering boxes and carts.

- Drives food safety, integrity and innovation.

- Reduces the cost of product loss.

Documentation

Loading the AIB

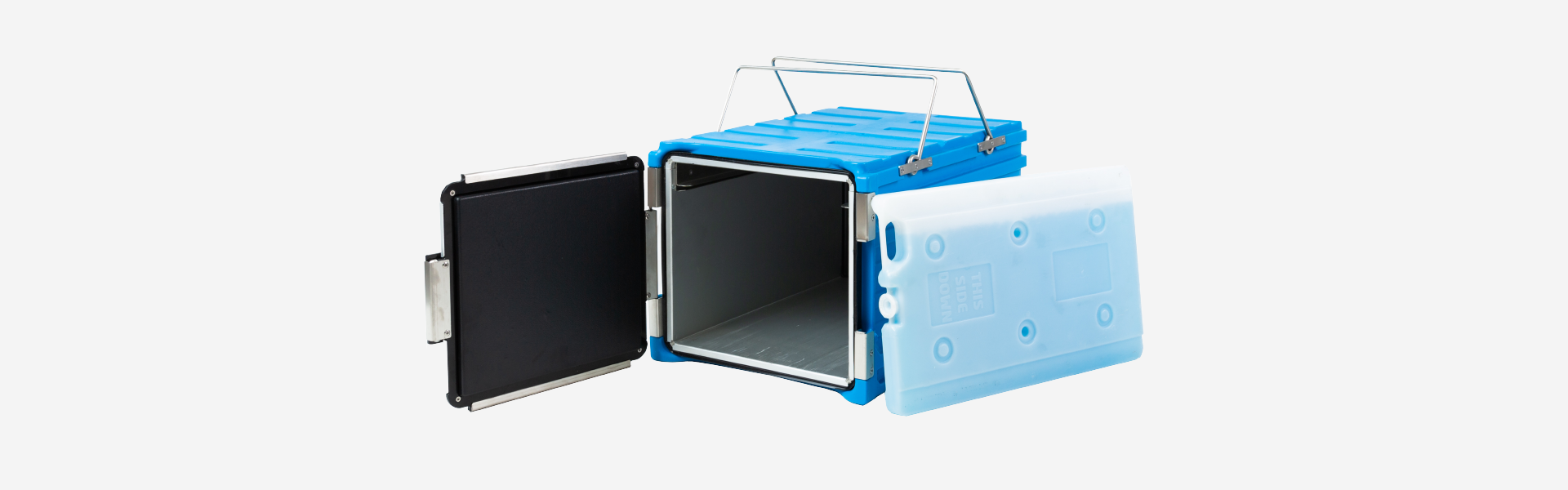

Product facts:

- They are extremely robust giving a longer routable life than other chilled solutions on the market.

- Our boxes maintain food temperature <+8°C for 24 hours

- Our boxes are a passive temperature-controlled packaging solution that has no mechanical parts that could fail or require complex maintenance.

- No need for dry ice

- 100% reusable

- Using Phase Change Material (PCM), not water-based gel packs, they deliver constant and consistent results.

- Our boxes are food graded or FDA “known safe”.

- Our boxes provide a flexible supply chain solution

- Class leading compliance and no requirement for human intervention during transit.

Tower onboard catering insulated box containers are designed to be used all year round to all destinations using one packaging instruction – avoiding extra levels of complication and uncertainty within either validation or operational control.

Tower’s global network operates common processes and standards delivering consistency for customers. The network offers customers access to the complete range of Tower’s products with a local team of experts available to understand specific customer needs: this ensures that Tower delivers, where and when needed.

Tower cold chain recognise the role we play in working with our stakeholders to move from a linear supply chain to a circular one – providing a solution that supports our mutual ambition of waste reduction through reusability keeping our containers in use for longer reducing the need for disposal and recycling of temperature controlled packaging.