Looking Back: Monitoring Vaccine Distribution Amid COVID-19

Four years on since the COVID-19 pandemic, our temperature-controlled systems continue to play a pivotal role in transporting life-saving pharmaceutical shipments across the globe. Central to this success is our ongoing partnership with InTemp, a global leader in IoT monitoring solutions specialised for cold chain and healthcare.

Challenge: Maintaining Ultra-Cold Temperatures for Vaccine Distribution

One of the most critical challenges in vaccine distribution during the pandemic was maintaining ultra-cold temperatures required for vaccines like those developed by Pfizer, AstraZeneca and Moderna which needed to be transported at subzero temperatures through some or all of their supply chain. Recognising the urgency and complexity of this task, Tower Cold Chain joined forces with InTemp to develop a solution capable of monitoring internal and external temperatures of Tower containers, accommodating ultra-cold to ambient conditions.

Solution: The InTemp CX405-RTD Gateway Device

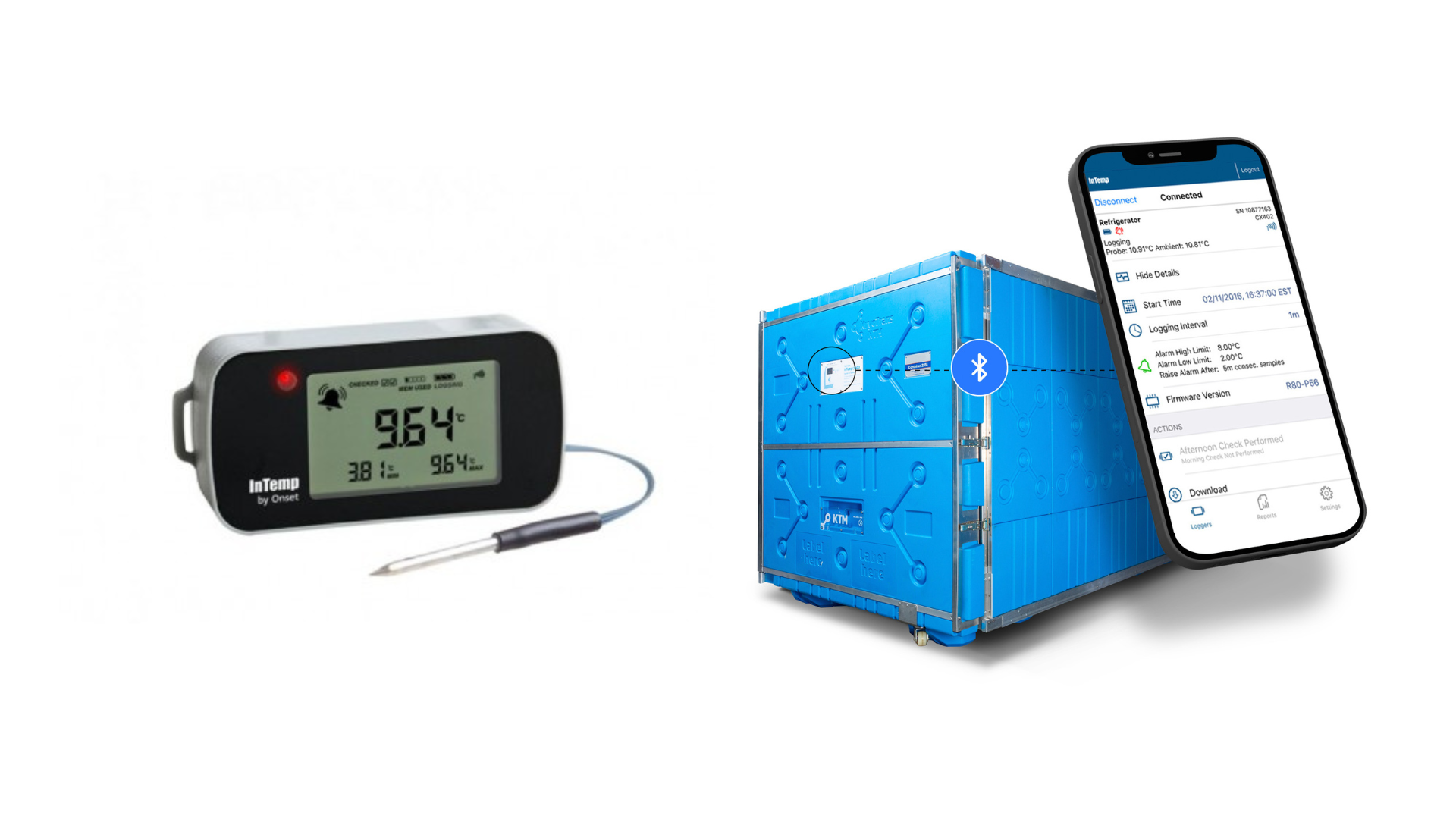

Tower Cold Chain and InTemp collaborated to develop the Bluetooth CX405-RTD probe data logger for ultra cold temperatures, a groundbreaking solution tailored to meet the unique requirements of pharmaceutical distribution. Integrated seamlessly into Tower’s range of passive temperature-controlled containers, this device plays a pivotal role in monitoring temperatures across international supply chains, particularly critical for preserving the efficacy of thermally sensitive vaccines.

Equipped with the InTemp CX405-RTD logger, all of Tower’s KT and KTM units provide comprehensive data visibility through the InTemp mobile app and can be synced with Tower’s Customer Control Centre (TCC) Portal. Precise internal and external temperature readings and alarm conditions can be seen visually and wirelessly without opening the container, streamlining the monitoring process for Tower’s operations.

When connected to the internet through InTemp’s Bluetooth CX Gateway device, which are strategically installed in over 23 Tower hubs worldwide, the gateways enable users to receive real-time alerts from the CX405-RTD data loggers and automatic reports as Tower units reach key distribution points during transit. Access to status of temperature conditions facilitates audits, quality control, and liability assessments, while also enabling proactive monitoring and intervention when deviations seldom occur.

The InTemp loggers play an additional vital role in ensuring optimal stock levels per hub, contributing to overall operational efficiency and inventory management within Tower’s network. The loggers have also played a vital role in an ongoing study between Tower Cold Chain and Cardiff University’s Business School, identifying derived strategies to reduce carbon emissions caused by non-value-added movements in cold chain distribution.

Partnership Evolution and Technical Innovations

Prior to the pandemic, the partnership between Tower Cold Chain and InTemp has evolved significantly since its inception in 2015. Initially centred around Bluetooth-enabled monitoring solutions, the collaboration has since expanded to incorporate sophisticated IoT infrastructure, including cloud-based platforms and, more recently mobile devices. This evolution reflects both companies’ commitment to continuous innovation and their dedication to addressing the evolving needs of the cold chain industry.

Claus Frykman, Global Sales Manager at InTemp, remarked, “Our partnership with Tower extends beyond a typical supplier-customer relationship. It’s based on trust, collaboration, and a shared commitment to safeguarding public health through the integrity of cold chain technology. Together, we’re dedicated to ensuring that life-saving pharmaceutical products reach their destinations reliably, efficiently, and with the highest standards of care.”

James Vann, Product Development and Innovation Manager at Tower Cold Chain, added, “Our nearly decade-long collaboration with InTemp has been innovation-driven. With so many pharmaceutical products requiring end-to-end security, data monitoring capabilities like those provided by InTemp are crucial for maintaining high levels of compliance and patient safety.”

Read more on how Tower ensures product integrity through digitalisation: https://www.towercoldchain.com/digitalization-in-supply-chains/