- Solution overview

- System Specifications

- Evaluation Criteria

- Documentation

Solution overview

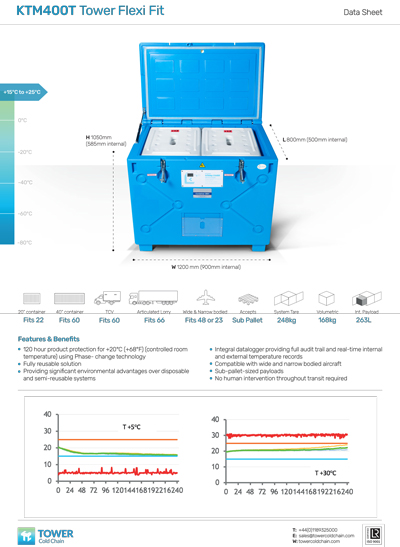

The Tower KT400 flexi fit container comes with unique pack-out options allowing for a multitude of different pharmaceutical packaging alternatives to be transported safely, simply and easily. It offers 120-hour product protection for -20°C (frozen), +5°C (refrigerated) and +20°C (controlled room temperature), using phase-change technology. All Tower KT400 flexi fit containers have a built in data logger which ensures door-to-door-compliant payloads with no human intervention throughout transit. Suitable for use with narrow- and wide-bodied aircraft, reefers and all road-transport options.

System Specifications

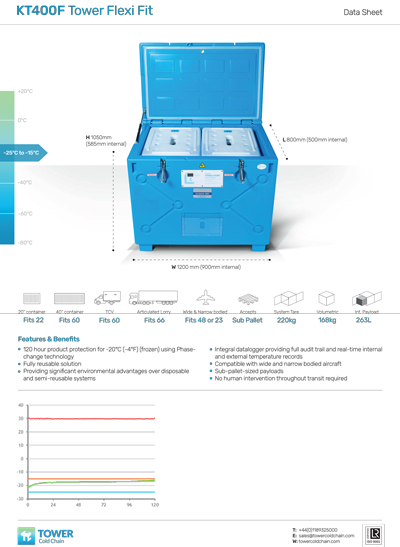

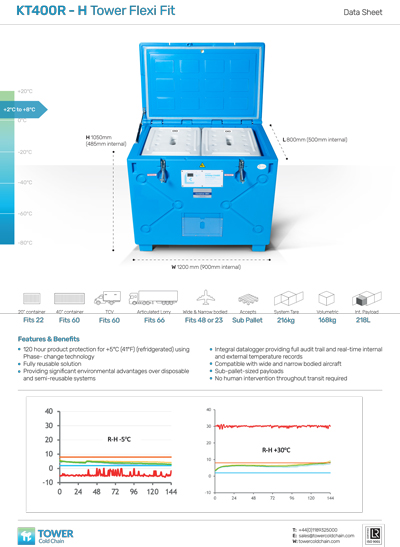

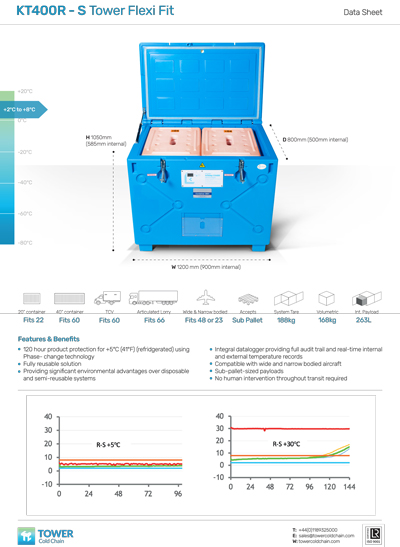

| KT System | Temp Range | External Dimensions | Internal Dimensions | Tare Weight |

|---|---|---|---|---|

| KT400T | +15°C to +25°C | L 1200mm x W 800mm x H 1050mm | L 900mm x W 500mm x H 585mm | 248kg |

| KT400R | +2°C to +8°C | L 1200mm x W 800mm x H 1050mm | L 900mm x W 500mm x H 585mm | 188kg |

| KT400F | -25°C to -15°C | L 1200mm x W 800mm x H 1050mm | L 900mm x W 500mm x H 585mm | 220kg |

| KT400D 025 packout | <-60°C | L 1200mm x W 800mm x H 1050mm | L 705mm x W 454mm x H 588mm | 228kg |

Evaluation Criteria

- 120 hours product performance -20°C (frozen), +5°C (refrigerated) and +20°C (controlled room temperature)

- Can be pre-conditioned and pre-configured ready for shipment

- Unique pack-out options allowing for a multitude of different pharmaceutical packaging alternatives to be transported safely, simply and easily.

- Suitable for wide and narrow bodied aircraft and all road vehicles.

- Fewer than 0.1% temperature excursions on average (data supported from over 15,000 shipments)

- Easy load and unload process through top door access

- No external power or human intervention required during transportation

- Integrated blue tooth data logger (RTCA DO 160G Part 21 H Compliant)

- Operational Qualification completed to customer loading and shipping specification.

- Global Qualification with near zero thermal mass which stress the containers far more than step tests, reducing associated documentation by half.

- Fully reusable circular supply chain solution.

- Easy and quick reconfigure for subsequent shipments.

- Global availability through our global hub network within 24 hours or less

- Global assurance, used by a wide range of pharmaceutical companies organisations

Documentation

KT400 flexi fit

The KT400 Tower Flexi Fit is ideally suited for the transportation of:

Primary Packaging:

- Sartorius Celsius® FFT shell system

- Varying drum sizes

- RoSS® containers

- Mylar bags

- HDPE bottles

- Nalgene bottles

- Single API drums

- Clamshells

- Cryoboxes

- Cylinders

- Mueller drums

- CurTec drums

Life Science Products:

- All vaccines, including C19 vaccines and ABIs

- API & diagnostic kits

- Biopharmaceutical solutions

- Diagnostics specimen samples

- Cell lines bacteria

- Micro organisms

- Proteins and other samples and solutions

- Clinical trial kits

- Any other product requiring a stable temperature environment for transportation

Data loggers are built into all KT400 Tower flexi fit containers, logging internal temperatures from -95°C (-139°F) up to 50°C (122°F). Users can get text or email notification of temperature excursions, as well as automatic data downloads throughout the transit (in-flight excluded) from loggers within range of the CX Gateway device. The loggers are built to FDA, USP, EU and WHO standards.

KT400 Tower flexi fit containers are designed to be used all year round to all destinations using one packaging instruction – avoiding extra levels of complication and uncertainty within either validation or operational control.

Tower’s global network operates common processes and standards delivering consistency for customers. The network offers customers access to the complete range of Tower’s products with a local team of experts available to understand specific customer needs: this ensures that Tower delivers, where and when needed.

Tower cold chain recognise the role we play in working with our stakeholders to move from a linear supply chain to a circular one – providing a solution that supports our mutual ambition of waste reduction through reusability keeping our containers in use for longer reducing the need for disposal and recycling of temperature controlled packaging.