Innovation Hub

Our product development team is dedicated to creating cutting-edge solutions that meet the evolving needs of industries such as pharmaceuticals, biotech, and food logistics. Every product we design reflects our commitment to maintaining the integrity of temperature-sensitive shipments across the global supply chain.

At Tower Cold Chain, we don’t just develop products—we create tailored solutions that safeguard your valuable shipments and optimise your supply chain.

Product Innovation

At the heart of our company ethos is a commitment to innovation, not just within our operations but also in how we empower and support our customers in designing and developing innovative solutions tailored to meet the challenges of today and tomorrow.

R&D driven developments

We continuously push product development boundaries, introducing new concepts through extensive research and testing. This innovation has resulted in number of patented products and technologies in multiple territories, showcasing our ability to create unique solutions that meet industry demands.

Market Driven Development

Our expertise in cold chain demands, regulations, and customer needs drives us to develop innovative, tailored solutions that ensure superior performance and compliance in challenging environments. This approach enables us to effectively address real-world challenges faced by customers.

Learn more about our latest innovation that increases thermal performance by 30% >

Customer-Driven Developments

If our existing product range doesn’t fully meet your needs, we’ll work with you from concept to launch to create a tailored solution. We also continually gather use case feedback to refine and improve the design of our solutions, ensuring ongoing product enhancement and satisfaction.

Case Study: Award Winning Solution designed for a Major British Airline >

Collaborative Innovation

We design flexible personalised and customised solutions that adapt to your needs. Our tailored approach streamlines qualification and ensures optimal protection, helping your business operate more efficiently.

Design drivers

At Tower Cold Chain, Customer Value is at the core of everything we do. Our design process ensures that we deliver Robust, Reliable, Reusable solutions that meet your evolving needs and can withstand demanding environments, ensuring longevity and consistent performance. By collaborating with our customers, we continuously enhance key aspects of our product offerings to deliver maximum value.

Scalability & Flexibility

We develop scalable products that can adapt to changing market needs and regulatory demands. Our containers are modular, making them easy to use and to scale for different shipment sizes or temperature ranges. This flexibility allows customers to use the same solution for a variety of shipping needs.

Cutting-Edge technology

We use top-quality materials and the latest technologies to deliver exceptional physical and thermal protection while optimising volumetric and weight efficiency. This ensures superior performance and durability, enabling multiple uses without compromising effectiveness.

Sustainability

Every Tower container is intentionally designed to minimise environmental impact throughout its lifecycle. We focus on optimised weight and volume, modularity, and durability, allowing for repair, reuse, and complete recycling at the end of its life cycle.

Quality

Our product design prioritises quality assurance, with containers built to last 5-10+ years for exceptional durability. Utilising Six Sigma methodology, we enhance the repeatability and reliability of our products, minimising defects and optimising performance.

Performance & Achievements

Tower has earned the King’s Award for Innovation in recognition of its KTM container – a thermally insulated passive pallet shipping system, with a patented modular construction design.

The KTM has filled a gap in the cold chain shipping market, with its design striking the optimum balance between volumetric efficiency, durability, and optimised weight. Employing a modular construction of roto-moulded parts, this produced a lighter, more robust and cost-effective option – up to 45% lighter than competitor products. This further improves the KTM’s sustainability credentials across all transport supply chains, offering a fully reusable, space-efficient solution.

All of our containers have patented features, from plates to cassettes and harness designs etc.. These patents are specifically focused on maximising volume efficiency and reducing the weight of our units, ensuring optimal performance and innovation.

Service Innovation

New hub Opening in 4 to 6 weeks

Our tower’s ability to open new hubs within 4 to 6 weeks highlights both our responsiveness to customer needs and our capacity to scale efficiently. This rapid deployment allows us to expand services seamlessly, meeting growing demand while maintaining flexibility and supporting sustained growth.

Dry Ice Capacity no matter the size

Our Universal Pallet, Sub Pallet, Double Pallet, Single Pallet shippers and Small box solutions are all engineered to perform reliably even in extreme conditions, including dry ice temperatures as low as -80°C, making them ideal for various cold chain applications and ensuring that no matter the size or type of shipment, our solutions maintain their integrity and functionality in ultra-cold environments.

Consistent Global Service

With strategically located hubs across three regions, we deliver the same standardized process, product, and service excellence every time. Certified to ISO standards, our team is rigorously trained to meet strict quality, regulatory, and compliance requirements. Our efficient “load and go” service proposition guarantees minimal downtime, delivering seamless, reliable support wherever you need it.

Reliable Container Availability

We ensure you have access to ready-to-use containers when you need them, meeting last-minute demands with ease. With a responsive 48-hour standard service proposition and an extensive global network, we guarantee rapid availability across all temperature ranges. Whether it’s a sudden request or a planned shipment, you can count on us.

You Scan. We collect: the Click and Collect Convenience

With Click and Collect, returning your small parcel shippers (KTEvolution 26 and KTEvolution 57) is effortless. Simply scan the QR code on the unit, and your lease ends immediately—no extra charges for return days. This quick process eliminates storage hassles and ensures you only pay for the time you use, giving you complete control and a seamless return experience.

Consultancy

We rigorously test both our products and those of our customers, ensuring they meet stringent performance standards and support our customer with Design Qualification (DQ), Operational Qualification (OQ) and Performance Qualification (PQ) with a robust suite of services.

Our expertise guarantees that every product meets the highest standards of performance, reliability, and efficiency.

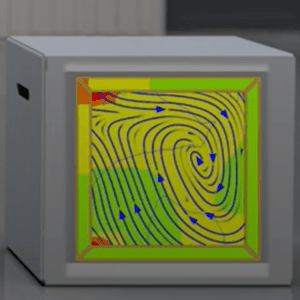

CAE Simulations

Our digital Computer Aid Engineering personalised simulation capabilities ensure regulatory compliance and reduce time-to-market, by integrating CAD designs with material values into a high-performance thermodynamic model to simulate heat and energy flows, optimising thermal weight and volume for maximum efficiency to ensure solutions meet design requirements while forecasting the performance of new and existing products.

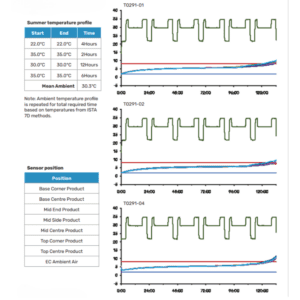

Operational Qualification

All our products come pre-qualified according to ISTA7D triplicate testing methodology summer and winter profiles; however, we also offer qualification support services to deliver personalised results tailored to your specific requirements or internal standards and processes.

Product & Distribution Testing

Our engineers conduct extensive physical and temperature testing using advanced offline chamber techniques to ensure every aspect meets stringent quality and regulatory standards. Physical testing includes drop, impact, vibration, handling, and low-pressure assessments to comply with ASTM and ISTA standards. While we outsource physical transportation testing, we manage the entire process to ensure comprehensive validation and compliance for distribution testing.

Consultative Product Development

If you are looking to develop a new product, our Consultative Product Development team provides a tailored approach. We partner with you throughout each phase—from initial idea to final launch—to create bespoke solutions designed to meet your unique needs.

Technology

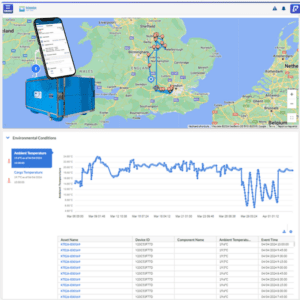

Monitoring & live Tracking

Our Supply Chain Intelligence platform Tower Control Centre (TCC) enhances the customer experience by providing real-time visibility, comprehensive monitoring, and simplified management of cold chain operations, ensuring greater control and efficiency. By leveraging this data we offer actionable insights, helping you make informed decisions that improve efficiency, reduce risks, and ensure the integrity of temperature-sensitive products throughout transit.

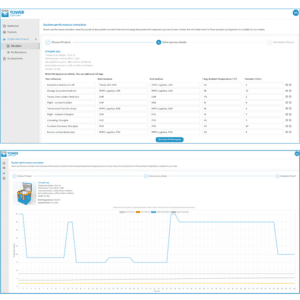

Lane risk assessment

For lane risk assessment, customers can utilise our online simulator via the Tower Control Centre (TCC) portal. By choosing the desired product and inputting details of the end-to-end journey, we can quickly generate a simulation that illustrates how your product will respond to under real-world thermal and logistical conditions, along with a corresponding simulation chart. This process leverages historical data obtained from our test chambers, allowing us to test and validate existing products with high precision.

Technical Hub

Welcome to our Knowledge Hub, where you can explore can easily access, download, and request essential documents such as product brochures, data sheets and Qualification reports.

The Technical Hub is designed to provide you with everything you need to make informed decisions and optimise your cold chain processes.