We ensure the protection of your animal healthcare products

Our team of experts works closely with your regulatory and quality teams to meet all your product protection requirements. With a range of containers and temperature-controlled solutions, from small box to double EU/US pallet sizes, we maintain visibility, efficiency, and stability throughout the entire process when transporting, storing, and distributing veterinary pharmaceutical drugs, vaccines, and biopharmaceuticals used for the treatment of animals.

Our sustainable range of temperature-controlled cold storage packaging solutions is designed to transport animal pharmaceutical products and can be used for all stages of that process from raw materials and clinical research to the finished product.

Containers are available at all temperatures – ultracold (-80°), frozen (-20°C), refrigerated (2-8°C) and controlled room temperature (+20°C) – and provide a minimum of 120+ hours temperature and product protection with advanced Phase Change Material (PCM) cooling plates or dry ice solutions depending our your requirements.

Ensure quality with end-to-end animal health supply chain visibility

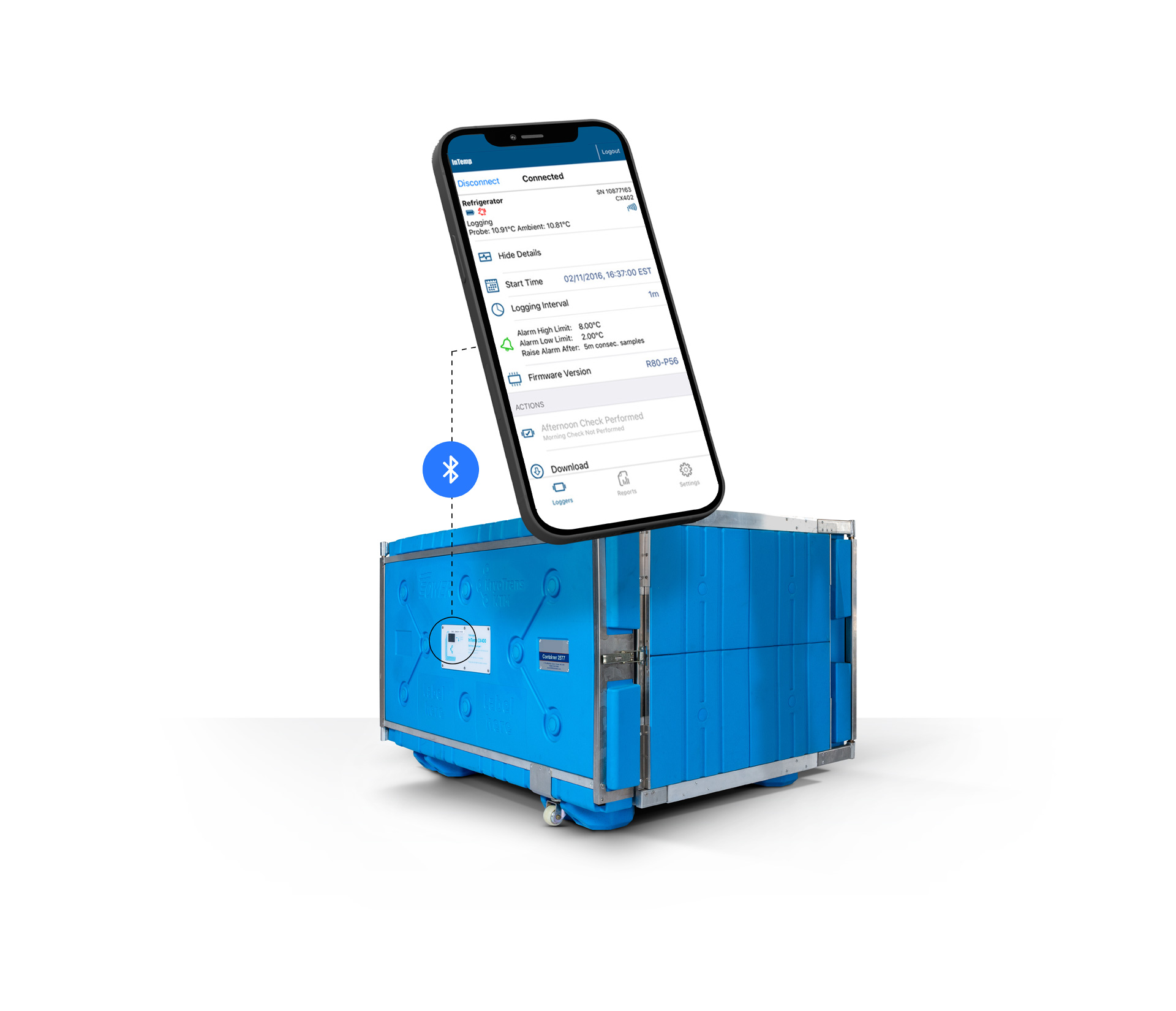

Tower delivers proven physical and temperature protection for veterinary pharmaceutical and biopharmaceutical products. The data loggers built into all Tower containers report bridges visibility gaps across your animal health supply chains allowing you to control and monitor your shipments preventing shipments from being spoiled or delayed, and ensuring the delivery of temperature-sensitive products on time and within budget.

Maintaining the efficacy and stability of your animal health products

Our temperature-controlled solutions are carefully designed to provide a minimum of 120+ hours of temperature and product protection for -80°C (ultracold), -60°C (ultracold), -20°C (frozen), +5°C (refrigerated) and +20°C (controlled room temperature) shipments (special temperatures from -40°C to +40 °C without dry ice).

Data downloaded from over 15,000 shipments has demonstrated fewer than 0.1% temperature excursions on average, a vital indicator in the maintenance of the cold chain. We achieve this by providing a reusable container that delivers the correct performance for every shipment. Our team focuses on delivering a consistent customer outcome whatever the location.

Multi-use, easy-to-use (portable) packaging solution

All players in the cold chain have a role to play in sustainability. We see ours as providing a reusable, cost-effective solution that contributes to customers’ circular supply-chain ambition. Customers value our long-term lease containers and supply-chain flexibility.

Find the right cold chain solution for you

Explore our range >Data logger

The veterinary and animal cold chain involves carefully controlling and monitoring the temperature range of the products during storage, transportation, and distribution.

The Data loggers built into all Tower containers, logging internal temperatures from -95°C (-139°F) up to 50°C (122°F) allow you to control and monitor your shipments through transit.

Users can get text or email notifications of temperature excursions, as well as automatic data downloads throughout the transit (in-flight excluded) from loggers within range of the CX Gateway device. The loggers are built to FDA, USP, EU and WHO standards.

Delivering value through customer-focused innovation

Tower incorporates innovation through design to meet the regulatory demands of the pharmaceutical supply chain. Our patented design technology meets the GDP requirements of our customers and exceeds the temperature-control demands of the pharmaceutical industry.

Our expert teams work closely with our customers, realising their requirements and how we can address emerging needs. Tower collaborates with stakeholders to identify challenges across a supply chain and to deliver customer-focused innovation.